1: Brief Introduction Of 17-4PH stainless steel

Alloy 17-4 is a chromium-copper precipitation hardening stainless steel that is used for applications requiring high strength

and a moderate level of corrosion resistance. It is one of the most widely used precipitation hardening grades, as it has high

strength hardness up to about 572°F while demonstrating good corrosion resistance in all heat treated conditions. Alloy 17-4

has adequate resistance to atmospheric corrosion or in diluted acid salts where its corrosion resistance is equivalent to Alloy

304 or 430. Alloy 17-4 can be heat treated to a variety of temperatures to develop a wide range of properties. Its mechanical

properties can be optimized with heat treatment where very high yield strength up to 180 ksi can be achieved. Alloy 17-4

should not be used at temperatures above 572°F or at very low temperatures.

Corrosion Resistance:

★Withstands corrosive attacks better than any of the standard hardenable stainless steels.

★Comparable to Alloy 304 in most media.

★Corrosion resistant in some chemical, petroleum, dairy, and food process industries.

★Subject to crevice or pitting attack if exposed to stagnant sea water for any length of time.

Weldability:

★Successfully welded by most common fusion and resistance methods.

★Should not be joined by oxyacetylene welding.

★Generally no pre-heating required.

★Inter-pass temperature must be limited to 248°F.

★Better toughness is obtained in the weld after a complete heat treatment.

Machinability:

★Can be machined in both solution-treated and precipitation-hardening conditions.

★Machining conditions may vary with hardness of material.

★High-speed tools or preferably carbide tools with standard lubrication are normally used.

Other Grades:

201,202,21-4N,301,302,301L,303,303Se,304,304L,304H,304LN,304N,305,S38400,308,309,309S,310,310s,

316,316L,316H,316Ti,316N,316LN,317,317L,317LMN,317LN,321,321H,347,347H,S3100,S31803,S3205,

S32304,S31200,S31260,S32507,405,409,429,430,430F,434,444,403,410S,410,416,420,420F,431F,440A

440B,440C,440F,610,630,631,632,635,660,Alloy 200,Monel 400 ,Alloy K-500 ,Inconel 600 , Incconel 601,

Inconel 625 , Inconel 718 , Alloy 800 ,Alloy 800H,Alloy 800HT,Inconel 825,Alloy 276, Alloy 20, Alloy 59

Chemical Properties:

| TYPE | Cr | Ni | Cu | Cb + Ta | C | Mn | P | S | Si |

| 17-4 (Alloy 630) | 15.0-17.5 | 3.0-5.0 | 3.0-5.0 | 0.15-0.45 | 0.07 max | 1.0 max | 0.04 max | 0.03 max | 1.0 max |

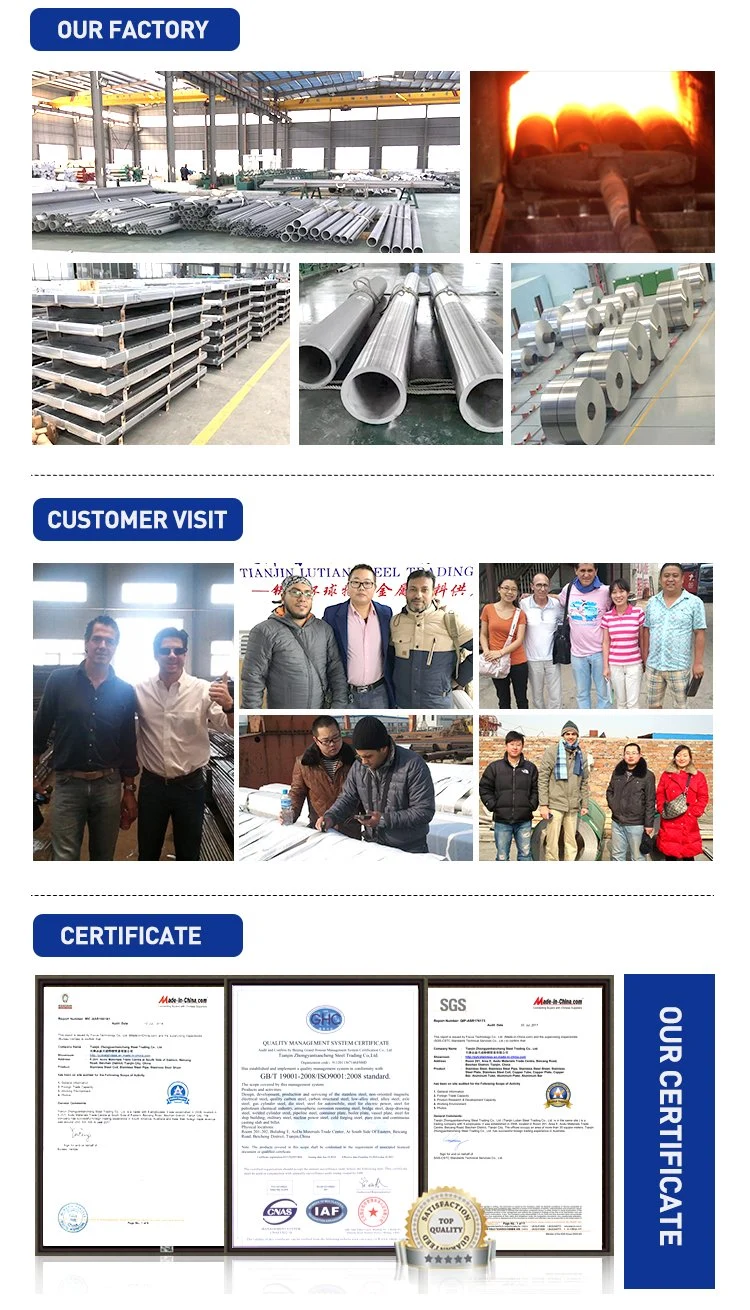

3: Packing & Shipping

4: Company Introduction