copper nickel alloy CuNi2si-C70260 Strip/Tape/foil/wire

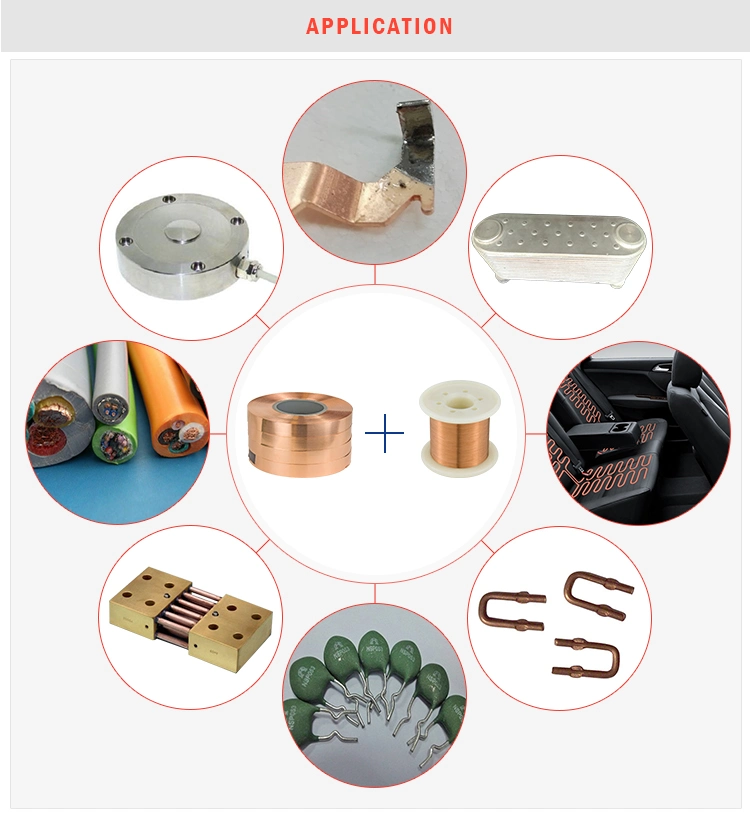

CuNi2Si -C70260 Nickel Silicon Bronze Alloys, which is an age-hardening alloy, higher alloyed in comparison with CuNi1.5Si, for current-carrying formed parts. It has an a-structure with very fine precipitations and recommends itself both for lead frames which require a high rigidity of the pins and for connector with high demands on the electrical conductivity, strength and relaxation behavior. In addition, the CuNi2Si can also be used for current-carrying formed parts and contact springs due to its good fatigue strength, forming and spring properties.

Mechanical Properties

CuNi2Si -C70260 Nickel Silicon Bronze Alloys, which is an age-hardening alloy, higher alloyed in comparison with CuNi1.5Si, for current-carrying formed parts. It has an a-structure with very fine precipitations and recommends itself both for lead frames which require a high rigidity of the pins and for connector with high demands on the electrical conductivity, strength and relaxation behavior. In addition, the CuNi2Si can also be used for current-carrying formed parts and contact springs due to its good fatigue strength, forming and spring properties.

Mechanical Properties

| Max Continuous Service Temp | 200ºC |

| Resisivity at 20ºC | 0.05±10%ohm mm2/m |

| Density | 8.9 g/cm3 |

| Thermal Conductivity | <120 |

| Melting Point | 1090ºC |

| Tensile Strength,N/mm2 Annealed,Soft | 140~310 Mpa |

| Tensile Strength,N/mm2 Cold Rolled | 280~620 Mpa |

| Elongation(anneal) | 25%(min) |

| Elongation(cold rolled) | 2%(min) |

| EMF vs Cu, μV/ºC (0~100ºC) | -12 |

| Micrographic Structure | austenite |

| Magnetic Property | Non |